Product Presentation

NOVEL PRODUCT INNOVATION

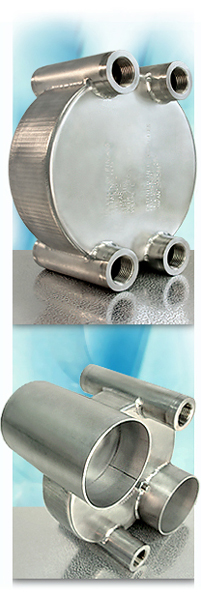

RauCell Plate Heat Exchanger has references of numerous customer applications starting from 1994.

EFFECTIVE AND SMALL, ENDURING

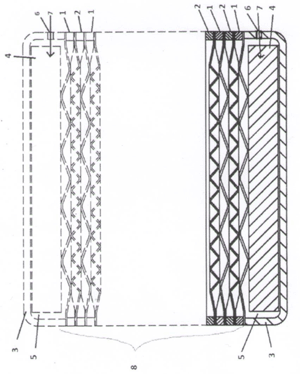

In heat transfer plates are no flow holes, which minimize heat transfer surface and restrict passage. The plates are welded on edge to form uniform and enduring shell.

OVERALL CONSTRUCTION OF ACID SUSTAINABLE STAINLESS STEEL, AISI316L

Primary and secondary circuits as well as all surfaces are of material AISI316L. Acid sustainable stainless steel is an excellent common place construction material. The plate spaces are clean and have no foreign metals.

PROFITABLE AND ENVIRONMENTALLY FRIENDLY

Heat Exchanger construction does not include brazing and aquatic poisonous metals as copper. It suits also well to chemical industries and food industry. Suitable as well to hygienic spaces.

THE CONSTRUCTION WITHOUT BRAZING AND GASKETS

The Heat Exchangers are wholly welded. There are no dissolving brazings and no leaking edge and hole gaskets.

JOINT SIZES TO CHOOSE, FLUSH AND WASH JOINTS READY

Joint sizes to choose are G1/2”, G3/4”, G1”, DN40, DN50, DN65, DN80, DN100. Circuits needing flush and wash can be equipped with extra joints.

WIDE APPLICATIONS OF USE

Water, fluids with water, steam, vapours, oils, hydraulic oils, hot oils, cold oils, burner oils, chemical fluids, gases, air, cold fluids as ammonia.

We cope with the EU Pressure Vessel Directive 97/23/EU. Allowed use pressures are from zero to 60 bars. Allowed temperatures of use from below zero to several hundred Celsius degrees, depending of the application.